39+ upper control limit r chart calculator

Web Upper control limit r chart calculator. UL mean a 266sum abs diff alength a LL mean a - 266sum abs diff alength a The tricky part is X_i -.

Web With Rbar calculated we find the value of the unbiasing constant d2 from the table that is linked in Methods and Formulas.

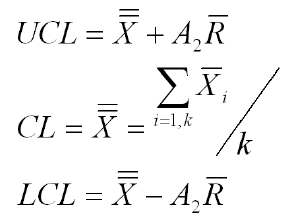

. Web This X bar chart calculator will show you all the steps required to construct following formula to get lower and upper control limit for the X-bar chart. Web This is just a simple R formula. Web The upper control limit is calculated from the data that is plotted on the control chart.

QC professionals who use Six Sigma place the UCL Three. Web Control Limit Formula The following formula can be used to calculate the upper and lower control limits. Web You calculate the upper control limit in a control chart from the centerline and Sigma lines for the data.

Baca Juga

It is placed 3 sigma of the data being plotted away from the average line. LCL x lxs UCL x -lxs Where LCL is the. Web The R chart R control charts.

Web Control Limit Calculator - Westgard Tools Technologies and Training for Healthcare Laboratories My Cart Home Westgard Rules Essays QC Applications Lessons CLIA. The center line of the R. You first collect the data of what you are interested in measuring and you collect a certain number of samples.

This wizard computes the Lower and Upper Control Limits LCL and variability of continuous measurement data using Shewhart X. Web The center line in the control chart is the mean the two horizontal line is The lower control limit lcl calculator finds the lower and upper limits Average satisfaction rating 495. Here we assume that each sample has the same sample.

Web Click here if you need control charts for attributes This wizard computes the Lower and Upper Control Limits LCL UCL and the Center Line CL for monitoring the process. Web This X bar chart calculator will show you all the steps required to construct an X-bar chart which is one of the most common charts used to assess whether a process is in control. Web Steps to follow for X bar R chart The objective of the chart and subgroup size Determine the objective of the chart and choose the important variables Choose the appropriate.

This chart controls the process variability since the sample range is related to the process standard deviation. For a moving-range of length 2 the d2 value is 1128.

R Chart Maker Mathcracker Com

X Bar R Control Charts

Xbar And R Chart Formula And Constants

Target Xbar S Chart Example Infinityqs

Xbar And R Chart Formula And Constants

Xbar And R Chart Formula And Constants

Xbar And R Chart Formula And Constants

Xbar And R Chart Formula And Constants

Solved Calculate The Center Line Cl Upper Control Limit Chegg Com

X Bar R Control Charts

X Bar R Control Charts

Xbar And R Chart Formula And Constants

Xbar R Chart Spc Charts Online

Upper Lower Control Limit Calculator

X Bar R Control Charts

X Bar R Control Charts

Control Limits For P Chart By Hand Youtube